Plastic Vacuum formingis actually a thermoforming companies popular technique that’s employed by experts to display all over the world but to receive it right, you require expertise which is only with a couple of businesses. If you’re interested about it, then you have to get someone who focuses on vacuum forming with many years of encounter.

The Practice entails Several stages whenever you’re doing this professionally. The following are the methods by which vinyl products can easily be molded and flipped to fit whichever size, style, or contour demanded.

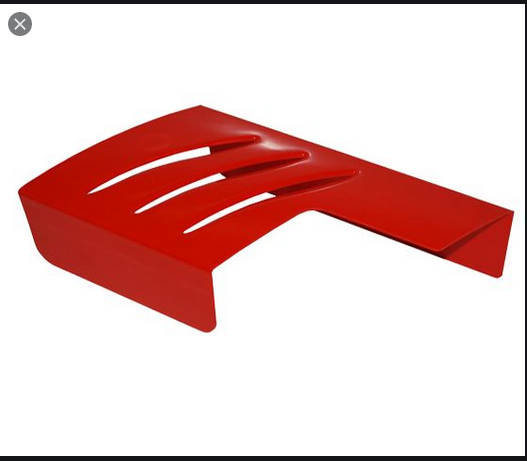

• Creating of this mold: The mould is constructed at the design which the vinyl should have the ability to produce around. The mildew could stem from several substances like MDFwood, wood, or even polyethylene. Where possible, be sure that the mould has edges that are angled. This can allow for the merchandise to soda from their plastic after the vacuum is completed.

• Setting the mold into the vacuum Once the mould Was shaped, place it right into a vacuum prior with a plastic sheet clamped on previously with out touching the mould

• The heater must be positioned above the vinyl: The heater that’s in the vacuum has to be placed above the plastic, which may then heat, warm the vinyl and ensure it is moldable and elastic.

• Move the shelf towards the vinyl: It must be achieved following some minutes at the correct temperatures, then utilize the handle to perform the job proceeding.

• Change the vacuum former: This may guarantee that all the air from your machine is already removed.

• Eliminate the sheet from the vacuum former: This should be performed after it has chilled. Remove the mould and eliminate any excess or unwanted from your sheet that’s shaped.